At Kupol we are pioneering the field of 3D printed energy-absorbing structures. We enhance safety for athletes and workers by leveraging the power of additive manufacturing technologies.

LET'S TALK ADDITIVE

Since 2019, Kupol has been engaged in a unique collaboration with other Canadian researchers in the quest for the ultimate football helmet.

The NFL Helmet Challenge has been an unmatched opportunity to show the world what 3D can do to protect the health of athletes but also to celebrate the power of multidisciplinary collaboration.

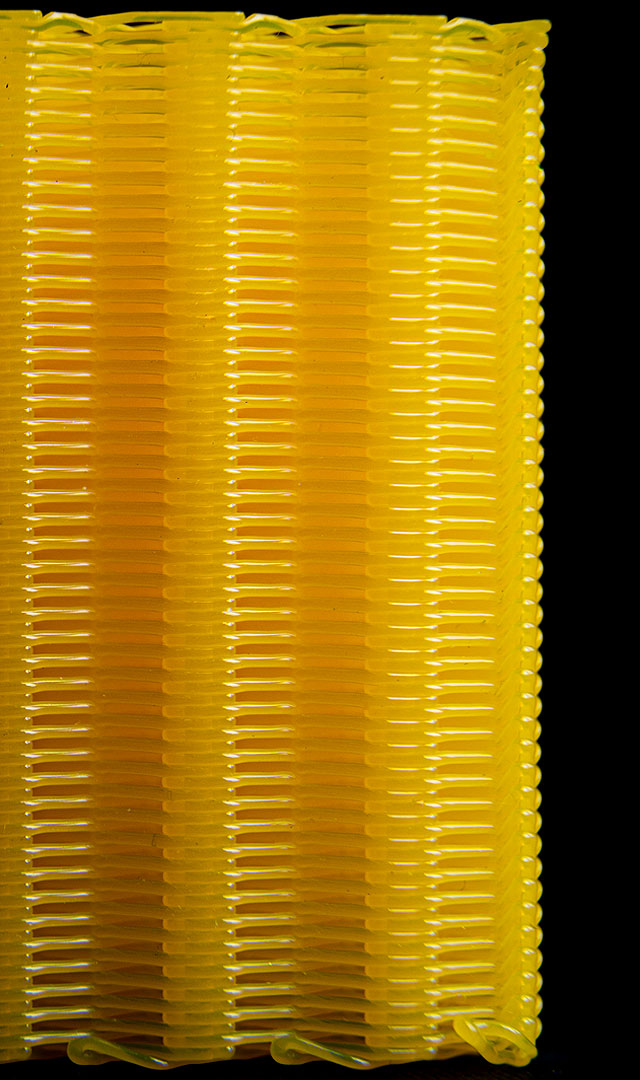

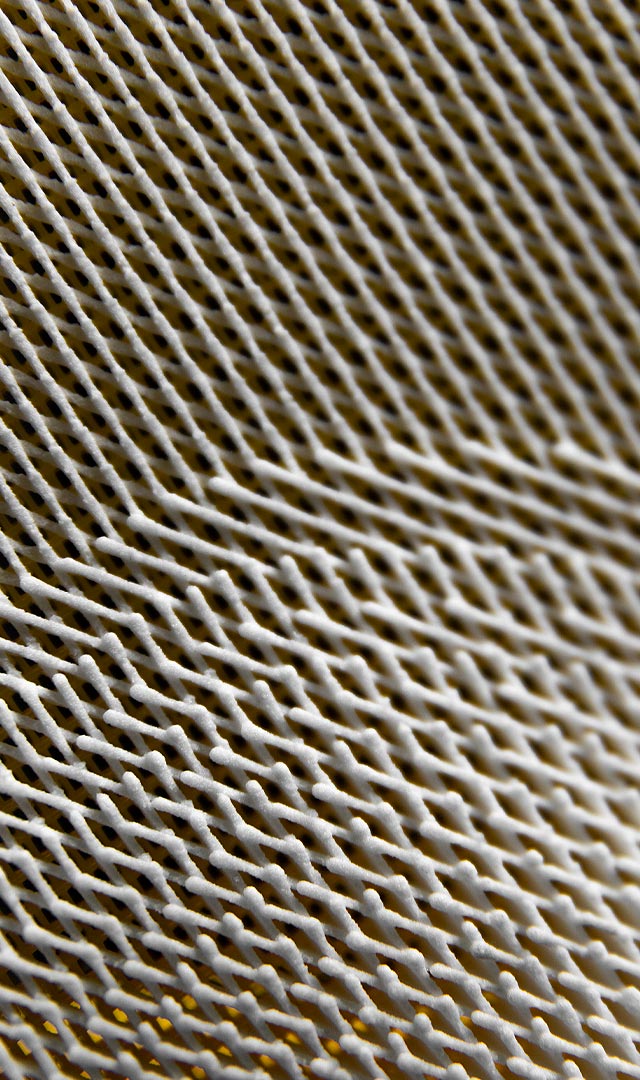

For two years, Kupol has been developing a novel approach to energy absorption by weaving polymeric strings to form Kollide's proprietary structures.

LEARN ABOUT KOLLIDE

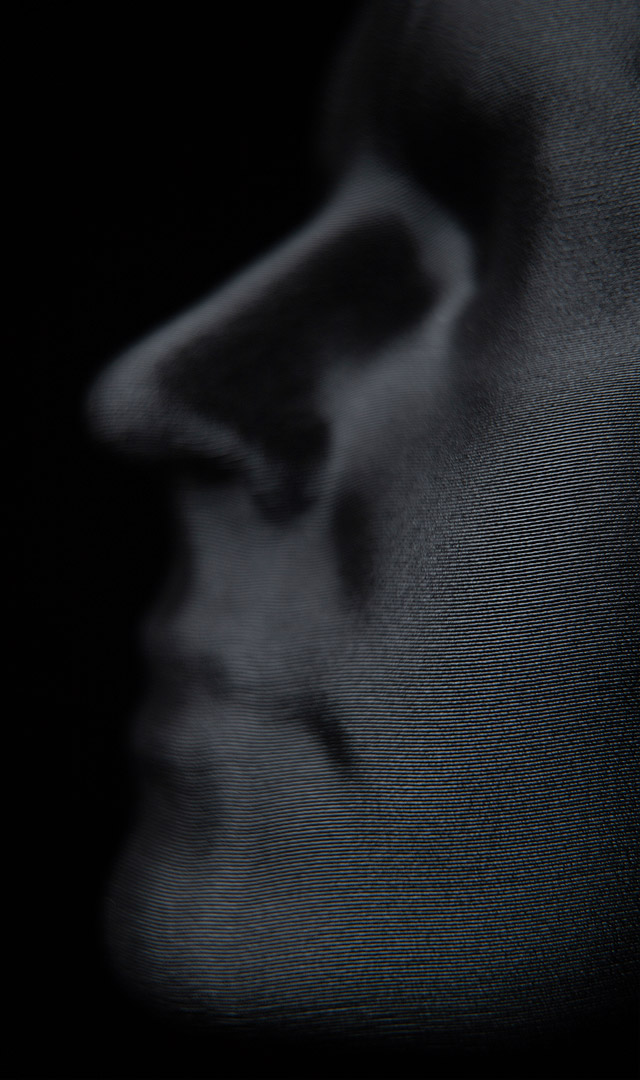

Fused Deposition Modeling (FDM) is only beginning to reveal its true potential. At Kupol, we are 100% devoted to pushing its boundaries.

Simultaneously using the X, Y, & Z axes alongside custom coding, we resolve challenges that were once impossible to overcome with traditional slicing.

For instance, printing completely hollow shells such as body parts is now possible, thanks to Kupol's work.

Additive manufacturing is more than a trend, it is the future of comfortable performance equipment.

WANT TO KNOW MORE

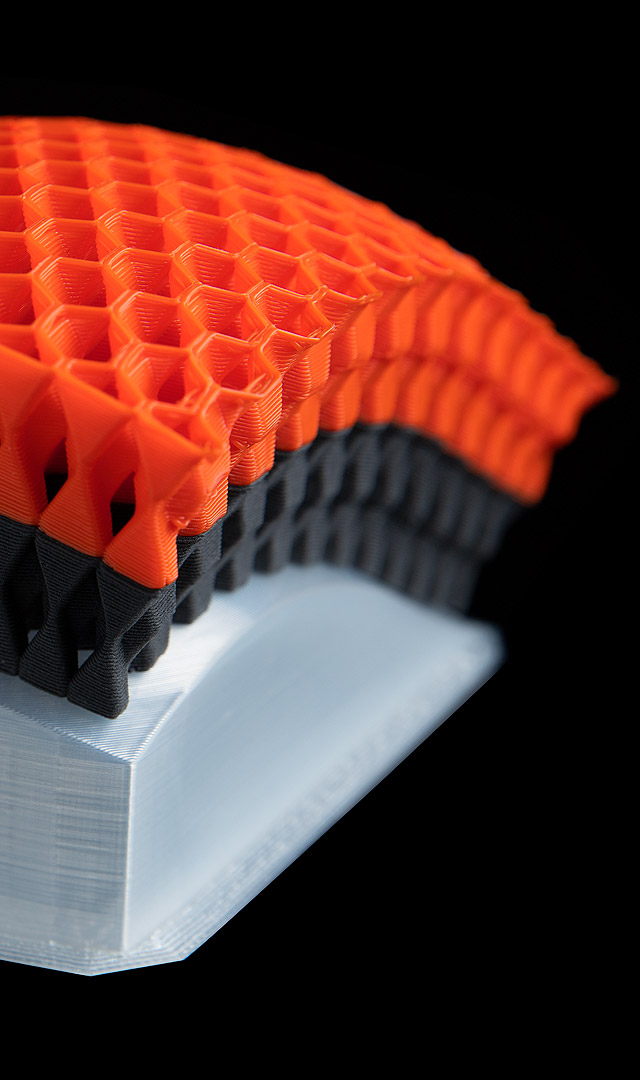

Since the early days of Kupol, we recognized the potential of geometry to push the performance of protective gear further.

Foreseeing the important role additive manufacturing would play in the 4th industrial revolution, we secured two patents regarding head protection through 3D printing.

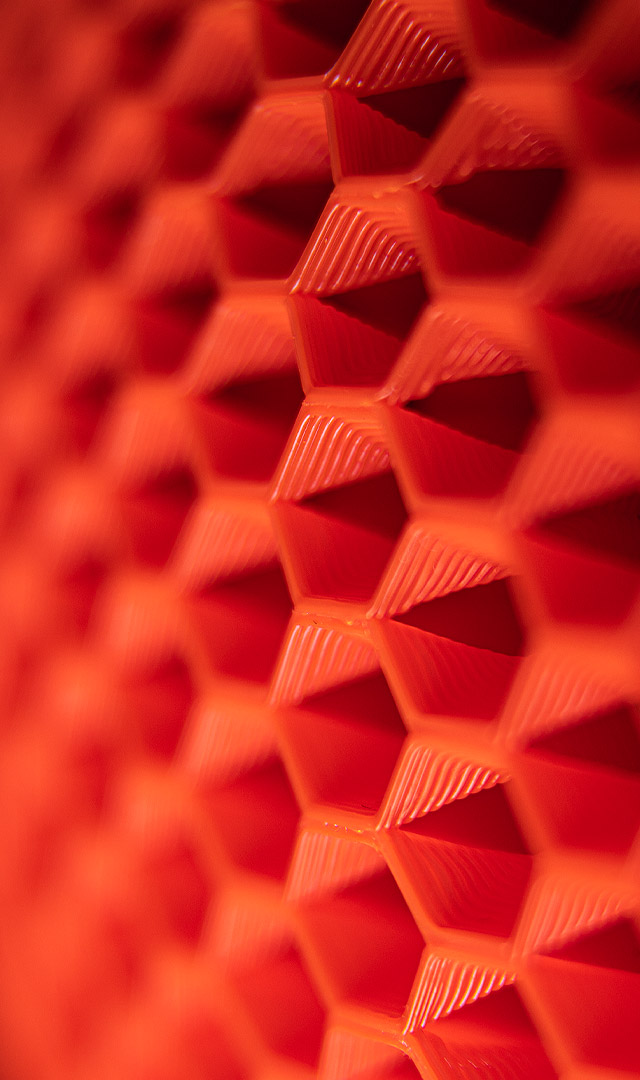

The cross-hexagonal pattern is unique to Kupol and is also capable of absorbing a large amount of energy.

FDM printing being the most affordable additive manufacturing process, we are committed to developing manufacturing solutions for the insole industry.

By lowering the entry barrier, we believe that a larger number of customers will enjoy the benefits of a custom insole and thus improve health.

Kupol operates with a very small team. This allows us to pivot on a dime in the direction that is now considered the most innovative and promising.

Its co-founder, Gabriel Boutin, works hands-on daily with both coding and printing. This allows us to iterate lightning-fast and to fine-tune our creation process.

LEARN ABOUT GABRIEL